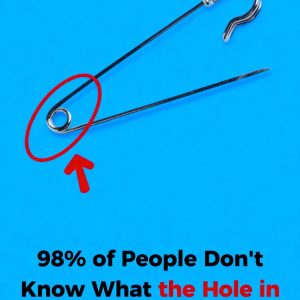

At first glance, a safety pin seems like one of the simplest tools you can keep in a sewing kit—nothing more than a curved piece of metal with a clasp. But tucked at the end of many safety pins is a tiny hole most people never notice. It’s not decorative, and it’s certainly not a manufacturing flaw. That small opening has a long, practical history rooted in traditional sewing techniques, and once you learn its purpose, you may find yourself using safety pins in an entirely new way.

For decades, seamstresses and tailors depended on safety pins for more than temporary fastening. That little hole was intentionally designed to guide elastic, ribbon, or drawstrings through narrow fabric casings. By threading a piece of yarn, string, or thin cord through the hole, you gain added control while pulling the pin through waistbands, hoods, sleeves, or hems. This simple method keeps the pin from flipping sideways, disappearing inside the fabric, or getting stuck halfway—annoyances that can turn a quick project into a tedious one.

This overlooked detail is a perfect example of how classic sewing tools were built with multifunctional features that modern users often forget. Before specialized gadgets and elastic threaders existed, makers relied on clever design to solve everyday problems efficiently. The safety pin’s tiny hole worked alongside other time-tested tricks—like waxing thread to reduce tangles or reinforcing seams with backstitches—to make sewing smoother and more reliable when precision mattered most.

Bringing these older techniques into today’s sewing projects doesn’t mean giving up modern convenience—it simply adds smarter options to your toolbox. Whether you’re adjusting a waistband, fixing a drawstring, or working on a handmade garment, understanding why tools are designed the way they are can save time and frustration. That small hole in a safety pin is a reminder that even the most ordinary items can contain ingenious solutions—you just have to know where to look.